- 94XXXXXX02

- XXXXXXX@XXX.com

- Category: Hydraulic Products and Equipment

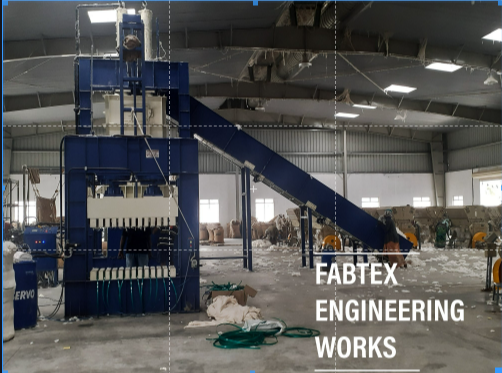

- Keywords: ### Auto Cotton/Waste Cotton Baling Press Machine with Conveyor by Fabtex Engineering Works **Introduction:**Fabtex Engineering Works introduces the Auto Cotton/Waste Cotton Baling Press Machine with Conveyor, an advanced solution for efficient and automated baling of cotton and waste cotton materials. This machine is ideal for textile industries, cotton processing units, and recycling centers, offering a seamless process from material feeding to compacted bales. **Key Features:** 1. **Automated Operation:** - The fully automated system minimizes manual intervention, increasing efficiency and productivity. The machine is designed to handle high volumes of cotton and waste cotton with minimal operator input. 2. **Integrated Conveyor System:** - The built-in conveyor streamlines the feeding process, ensuring a continuous and smooth flow of materials into the baling press. This enhances operational efficiency and reduces labor costs. 3. **High Compression Force:** - Equipped with a robust hydraulic system, the baler delivers significant compressive force to produce dense and uniform bales. This ensures optimal space utilization during storage and transportation. 4. **Sturdy Construction:** - Built with high-quality materials, the baling press is designed for durability and longevity. Its robust construction ensures reliable performance even in demanding industrial environments. 5. **User-Friendly Control Panel:** - The intuitive control panel allows operators to easily manage and monitor the baling process. Adjustable settings enable precise control over bale size and density. 6. **Efficient Bale Ejection:** - The machine features an efficient bale ejection system that allows for easy removal of compacted bales, minimizing downtime and enhancing productivity. 7. **Safety Features:** - Multiple safety mechanisms, including emergency stop buttons, safety interlocks, and protective guards, ensure a safe working environment for operators. 8. **Energy Efficiency:** - Designed with energy-saving components, the machine minimizes power consumption while maintaining high performance, reducing operational costs and supporting sustainable practices. **Technical Specifications:** - **Compression Force:** High-powered hydraulic system- **Motor Power:** Efficient motors for continuous operation- **Control System:** Advanced, user-friendly control panel- **Construction:** Heavy-duty steel frame- **Bale Size:** Adjustable to meet different material requirements- **Conveyor System:** Integrated for continuous material feed **Applications:** 1. **Textile Industries:** - Ideal for compacting waste cotton and leftover materials from textile production, ensuring efficient waste management and recycling. 2. **Cotton Processing Units:** - Streamlines the baling of processed cotton, enhancing storage and transportation efficiency. 3. **Recycling Centers:** - Efficiently compacts waste cotton, making it easier to handle, store, and transport for recycling purposes. **Benefits:** 1. **Increased Productivity:** - The automated operation and integrated conveyor system significantly increase the efficiency and speed of the baling process, boosting overall productivity.

- Manufacturer Name: Fabtex Engineering Works

- Packing size:

- Price: ₹2,600,000

Description

### Auto Cotton/Waste Cotton Baling Press Machine with Conveyor by Fabtex Engineering Works **Introduction:**Fabtex Engineering Works introduces the Auto Cotton/Waste Cotton Baling Press Machine with Conveyor, an advanced solution for efficient and automated baling of cotton and waste cotton materials. This machine is ideal for textile industries, cotton processing units, and recycling centers, offering a seamless process from material feeding to compacted bales. **Key Features:** 1. **Automated Operation:** - The fully automated system minimizes manual intervention, increasing efficiency and productivity. The machine is designed to handle high volumes of cotton and waste cotton with minimal operator input. 2. **Integrated Conveyor System:** - The built-in conveyor streamlines the feeding process, ensuring a continuous and smooth flow of materials into the baling press. This enhances operational efficiency and reduces labor costs. 3. **High Compression Force:** - Equipped with a robust hydraulic system, the baler delivers significant compressive force to produce dense and uniform bales. This ensures optimal space utilization during storage and transportation. 4. **Sturdy Construction:** - Built with high-quality materials, the baling press is designed for durability and longevity. Its robust construction ensures reliable performance even in demanding industrial environments. 5. **User-Friendly Control Panel:** - The intuitive control panel allows operators to easily manage and monitor the baling process. Adjustable settings enable precise control over bale size and density. 6. **Efficient Bale Ejection:** - The machine features an efficient bale ejection system that allows for easy removal of compacted bales, minimizing downtime and enhancing productivity. 7. **Safety Features:** - Multiple safety mechanisms, including emergency stop buttons, safety interlocks, and protective guards, ensure a safe working environment for operators. 8. **Energy Efficiency:** - Designed with energy-saving components, the machine minimizes power consumption while maintaining high performance, reducing operational costs and supporting sustainable practices. **Technical Specifications:** - **Compression Force:** High-powered hydraulic system- **Motor Power:** Efficient motors for continuous operation- **Control System:** Advanced, user-friendly control panel- **Construction:** Heavy-duty steel frame- **Bale Size:** Adjustable to meet different material requirements- **Conveyor System:** Integrated for continuous material feed **Applications:** 1. **Textile Industries:** - Ideal for compacting waste cotton and leftover materials from textile production, ensuring efficient waste management and recycling. 2. **Cotton Processing Units:** - Streamlines the baling of processed cotton, enhancing storage and transportation efficiency. 3. **Recycling Centers:** - Efficiently compacts waste cotton, making it easier to handle, store, and transport for recycling purposes. **Benefits:** 1. **Increased Productivity:** - The automated operation and integrated conveyor system significantly increase the efficiency and speed of the baling process, boosting overall productivity.