- 98XXXXXX08

- XXXXXXX@XXX.net

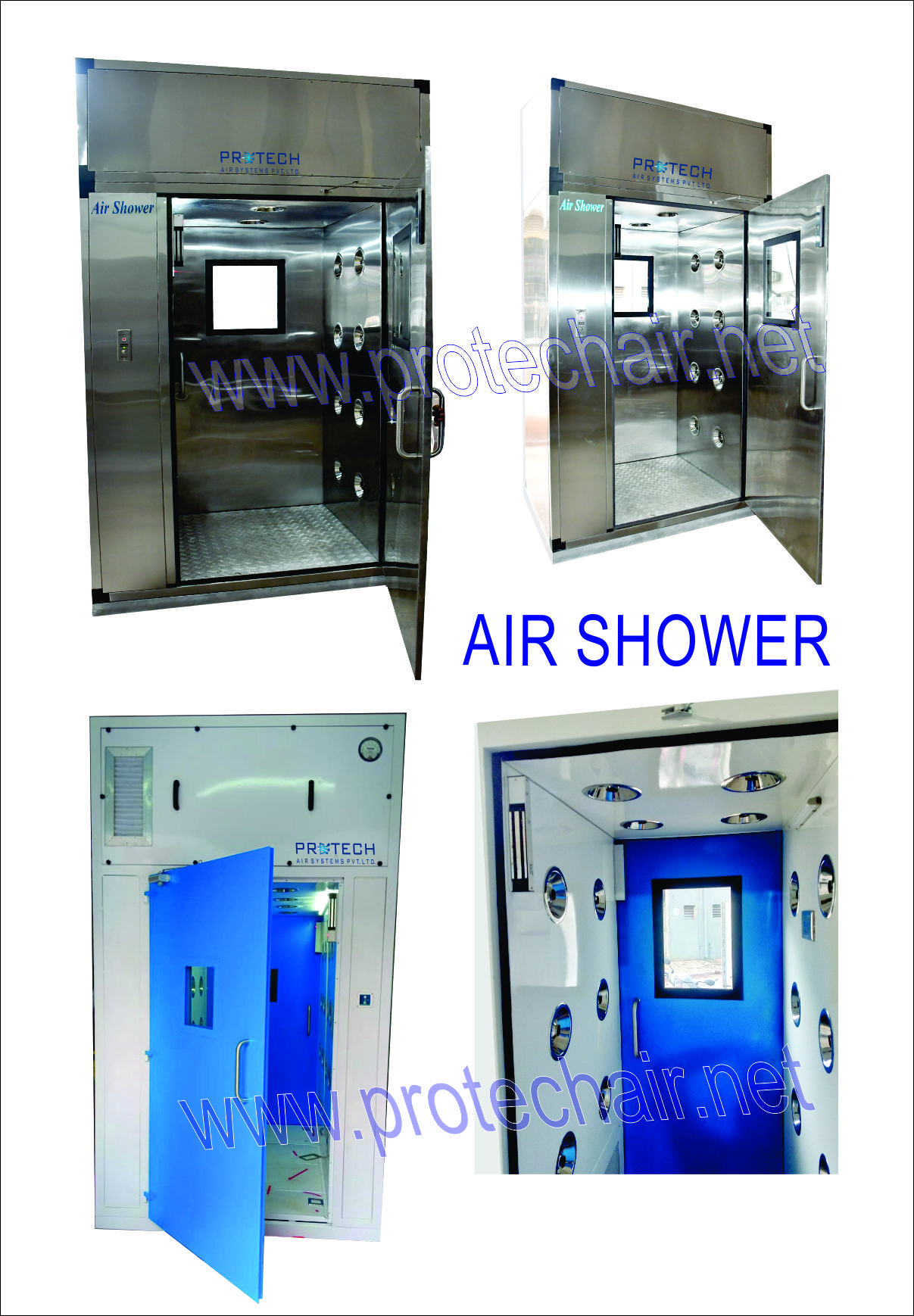

- Model No: PAS

- Category: Pharmaceutical Machinery and Equipment

- Keywords: Air Shower, Clean Room Air Shower, Clean Room Entry,

- Manufacturer Name: PROTECH

- Packing size: Depend on Equipment Size

- Price: ₹150,000

Description

Prefabricated modular Air Shower Unit used for removing surface particle from personnel prior to entering a contamination controlled environment. Air shower are constructed as per ISO 14666. Specification: Material of Construction Main Structure do with MS Powder Coated / S.S. 304 construction Inside Working Area : MS Powder Coated / S.S 304 Bottom do with Aluminum Checker Plate Both Side Entry / Exit Door : S.S / GI Powder Coated duly Double Skinned Blower Assembly Statically and dynamically balanced Motor & Blower, designed for supply of sufficient capacity and static pressure to take care of airflow Doors Automatic swing, micro-processor controlled electromagnetic inter locking doors with glass panels. (Comprising with Door Closure, ‘D’ Handle, Ball Bearing Hinges) HEPA Filter HEPA Filters down to 0.3mic. particulate at an efficiency of 99.999% (H14) duly tested on PAO tested Make-up Air Filter Pre-Filter down to 5mic. Particulate at an efficiency of 95% (EU5) enclosed in aluminum frame with epoxy sealing (Washable Type) Return Air Filter Pre-Filter Filter down to 5mic. Particulate at an efficiency of 95% (EU5) enclosed in aluminum frame with epoxy sealing (Disposable Type) Nozzle All Nozzles with S.S. 304 Door Interlocking Door Opening with Solid State Electronic Inter Locking Mechanism Operation Sequence:- First Cycle of operation: When D1 & D2 are Closed (Both Door are in locked condition), Blower in off condition When D1 is Opened (Door D2 gets locked condition), Blower in off condition When D1 is closed (Door D2 still in locked condition), Blower will be on when both doors are in locked condition Blower motor (As per timer setting) gets off and then Door D2 gets opened / unlocked, D1 in locked condition Door D2 is closed condition Door D1 / D2 gets opened / unlocked At a time only one door can opened Emergency Stop/Unlock Button provided at Entry / Exit/ Inside chamber